Product Drop Testing

Handheld and mobile products including smart phones, mobile phones, radios, remotes and other gadgets are becoming increasingly complex yet are being subjected to more abuse than they have ever before. Drop testing is used to assess the fragility of these products by subjecting them to repeatable impacts similar to those they will experience with an end user.

Every time a new device hits the market it’s quickly followed by multiple YouTube videos of first time users running informal drop tests. The problem with leaving this type of testing to the customer is you have next to no control over repeatability. Product comparisons are next to useless unless you’re dropping from the same height, in the same orientation, on the same impact point.

Our testers are designed to drop test products up to 230kg in weight from a repeatable height in varying orientations, ensuring that the testing you conduct provides solid data to gauge product weakness. We have a range of drop testing equipment including testers for small handheld item, all the way to large format drop on a Lansmont PDT-227 tester.

What kinds of products?

Drop testing is typically performed on small products that are either used in the hand, or in mobile situations. Any piece of equipment that can possibly be dropped should be drop tested during development to ensure you’re not up for surprises. A list of typical products we can test includes:

Cellphones, mobile phones, smartphones

Tablets

Two-way radios, mobile radios

GPS units, both handheld and vehicle mounted

Remote controls

Transmitters & receivers

Mobile EFTPOS units

Power Distribution Mobile Units

Flash drives, hard drives and pen drives

Medical devices

Test equipment including handheld meters

Tools, analysis equipment and more.

Torches, head mounted illumination, etc.

Drop testing standards

Whilst there are many standards available for use most of the time the standard leaves it to you to determine the right drop height and provides a minimum quantity of drops to perform on each face, corner and edge. We’re able to help with recommendations for drop testing, so if you’re in need of help just contact us.

A list of common standards, though not entirely comprehensive, includes:

MIL-STD-810

IEC 60601-1

IPC/JEDEC 9703: Mechanical Shock Test Guidelines for Solder Joint Reliability

JEDEC 22B110A: Subassembly Mechanical Shock

JEDEC 22B104C: Mechanical Shock

JEDEC 22-B111: Board Level Drop Test Method of Components for Handheld Electronic Products

MIL-STD-202

IEC 60068-2-27

IEC 60950

GR-63-CORE

DEF-STAN-0035

DO-160

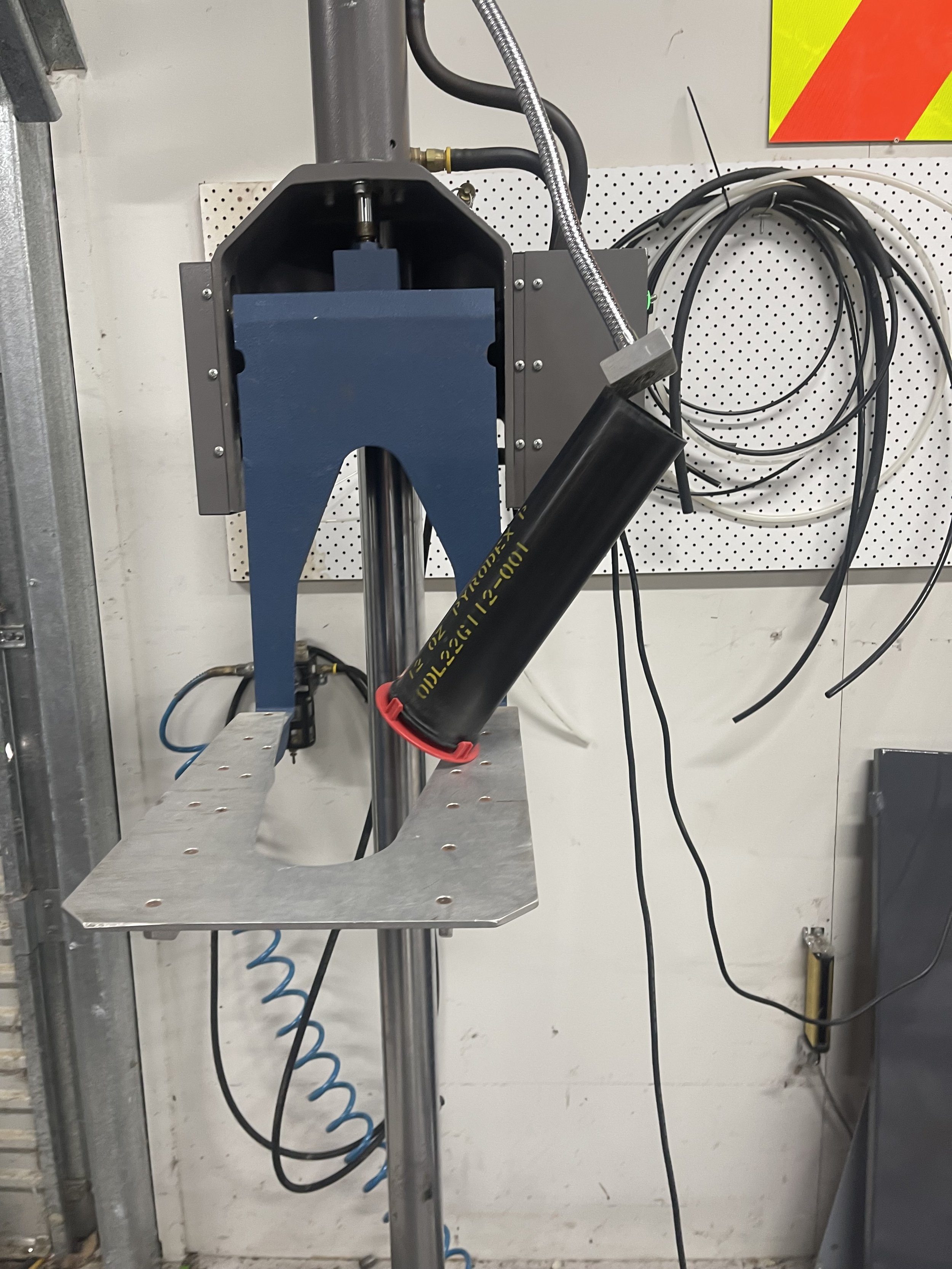

Our Heina DT2000

Drop Height Range: 600 – 2000mm

Velocity Range: 3.5 – 6.25 m/s

Specimen Weight: 1 – 2500 grams

Drop Method: Suction cup release

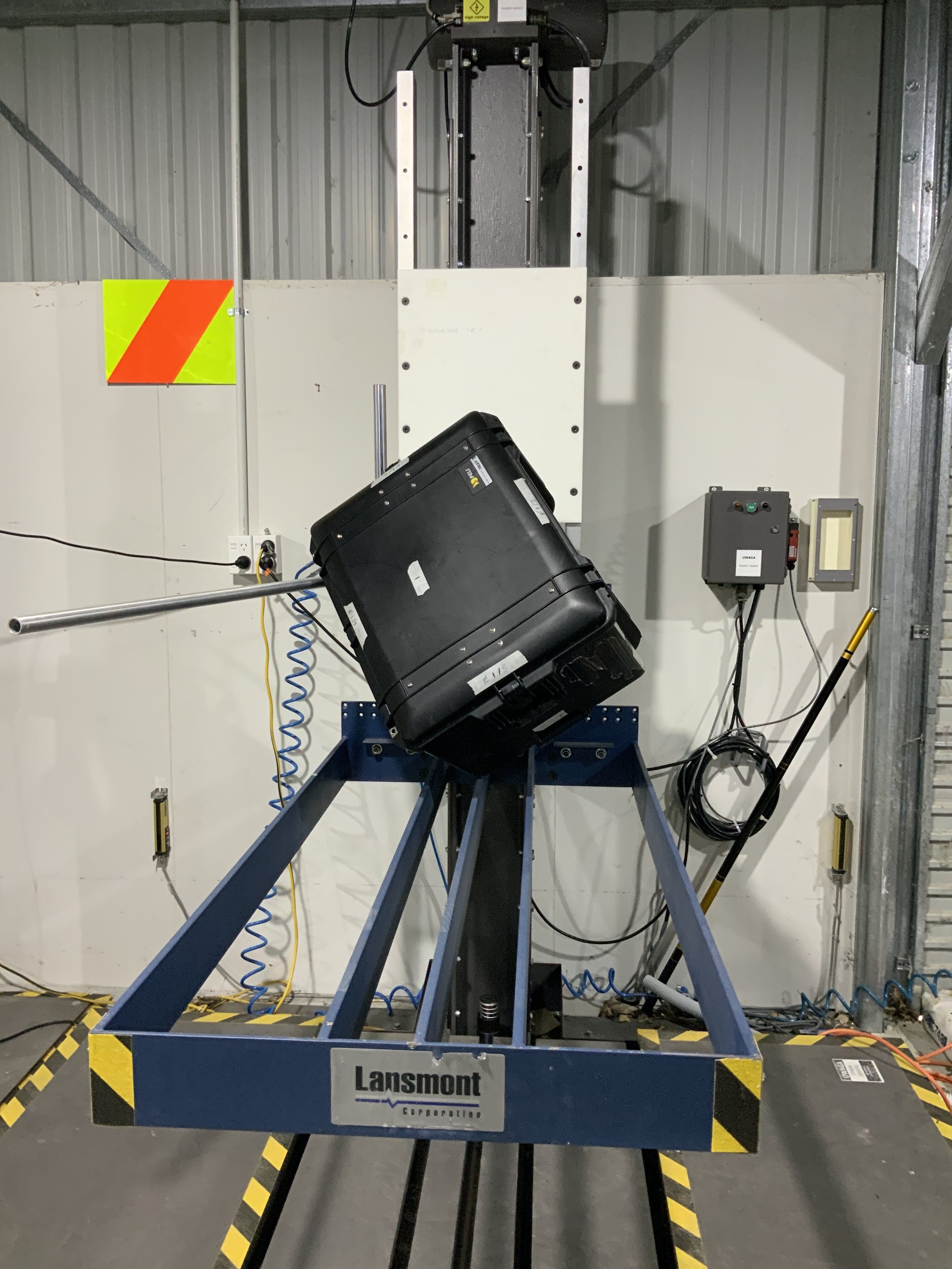

Our Lansmont PDT-227

Drop Height Range: 0 – 1850mm

Velocity Range: Free Fall with Carriage

Specimen Weight: < 230Kg

Drop Method: Free Fall on Carriage

Our Lansmont PDT-56

Drop Height Range: 400 – 2250mm

Velocity Range: Free Fall

Specimen Weight: < 80Kg

Drop Method: Pneumatic platform release