Package Testing :: ISTA ++

Package testing is an essential requirement for any product being shipped either domestically, or internationally. The hazards a packaged product is exposed to during transport are well documented, and there are numerous international test standards that provide options for testing - we support many and tend to only hit limits of high-displacement vibration test requirements.

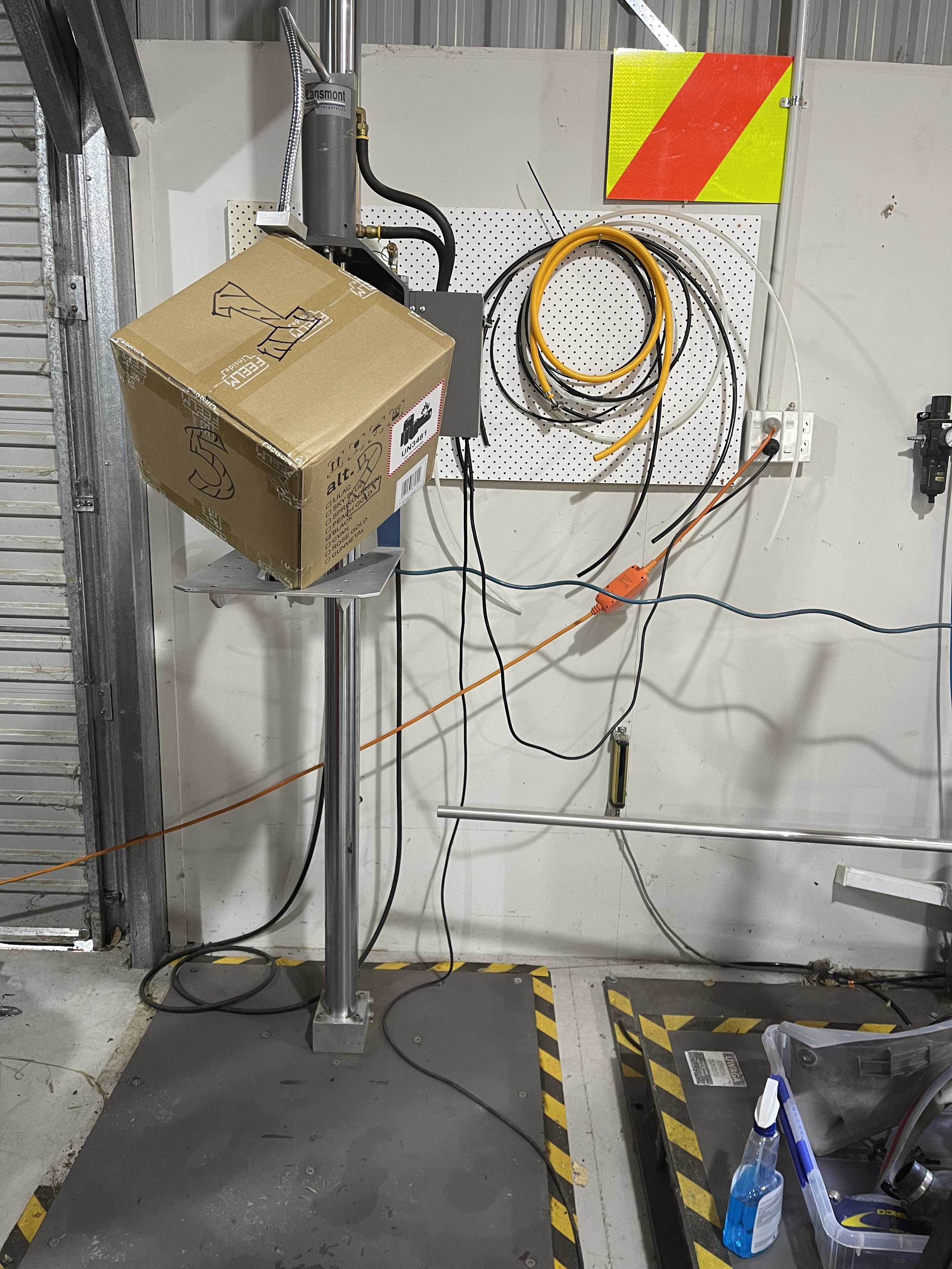

At our lab in Canterbury, NZ we operate Electrodynamic Shakers capable of performing transport vibration, package drop testers for dropping samples from 5-500kg and from 2 meters or below, and a compression tester for performing warehouse and truck stacking tests. Additionally we have a suite of Espec Corporation Environmental Chamber for pre-conditioning and conditioning prior to the application of stress.

We help companies who are suffering damage in transit often - and typically the cause of this damage is the application of multiple stresses in combination. Heat + vibration, or cold + vibration are two tests that tend to really stress the seals of a packaged product. We test for the food & beverage industry, medical and honey, beer (beer!) and wine, and standard consumer electronics.

Want to know what stresses your product is encountering? Talk to us about hiring one of our transport recorders and find out.

When is a good time to test?

We recommend that package testing be performed towards the end of the prototyping phase, or early in pilot production to ensure the product, and packaging configuration are close to the final iteration. Package testing should be conducted on products as they will leave the manufacturing facility. The internal support system of your package is a key element to customer satisfaction - nobody wants an abrasion or impact damage product to arrive.

Typical Test Process

Items that are not hazardous nature, and are not subject to sterility requirements fall under general packaging. Packaging of equipment such as consumer, or commercial electronics, toys, robotics, and mechanical items all come under this type of packaging. For general packaging the following tests are typically performed.

Pre-Conditioning, and/or conditioning (environmental / climatic pre-stress)

Temperature, humidity, and pressure

Vibration – sinusoidal and/or random

Shock Testing

Drop Testing

Compression Testing

Impact Testing

Equipment List

We operate the following packaging testing equipment - some of the world’s best.

Espec Corporation (Japan) Environmental Test Chambers

Lansmont Model 152-30K Compression Tester

Lansmont Model PDT-80 Drop Tester

Lansmont Model PDT-227 Drop Tester

LDS V850 Electrodyamic Shaker

Test blocks, dunnage bags, post bags, you name it.

Packaging Test Standards

ASTM Test series.

ISTA Procedures

ISO general packaging test series.

ISO 11607: Packaging for terminally sterilized medical devices.

EN 868-1: Packaging Materials and systems for medical devices which are to be sterilized.