Corrosion Testing :: Salt Spray + Cyclic

Corrosion testing targets metals, coatings, fasteners and other items used outdoors. Salt spray is the base-method with cyclic corrosion building on the learnings from this. We operate two salt spray / cyclic corrosion test chambers right here in Canterbury, New Zealand and can conduct testing to a wide range of standards.

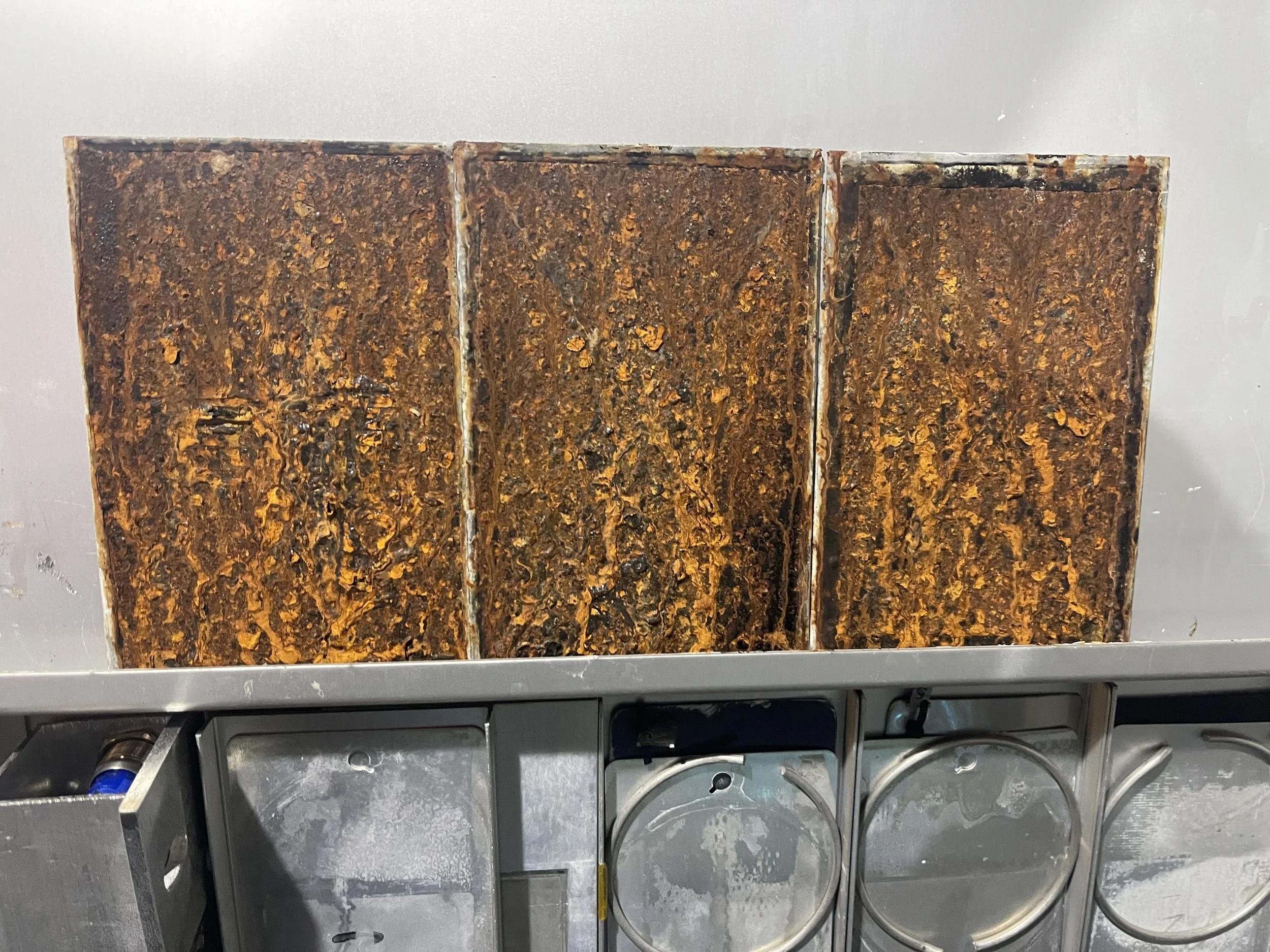

Some materials benefit more than others from cyclic corrosion - galvanised products in particular show better results as the white zinc oxide layer is allowed to form without being attacked from constant salt and water. This self-protection is what makes galvanised coatings (when done right) last an extreme amount of time. Stainless on the other hand may require a more aggressive copper-acetic test, where the pH is lowered to acid form to encourage corrosion.

Whilst many suppliers claim to conduct their own testing we’ve seen over and over again the difference between testing performed in New Zealand versus overseas. When profits come before reliability coating thickness, application process and quality all slip.

We’ve been running corrosion testing for over 10 years, and would love to help your next project. Whether thats a supplier quality check, batch test, or benchmarking test we’d love to help.

Salt Spray Testing :: The Classic Method

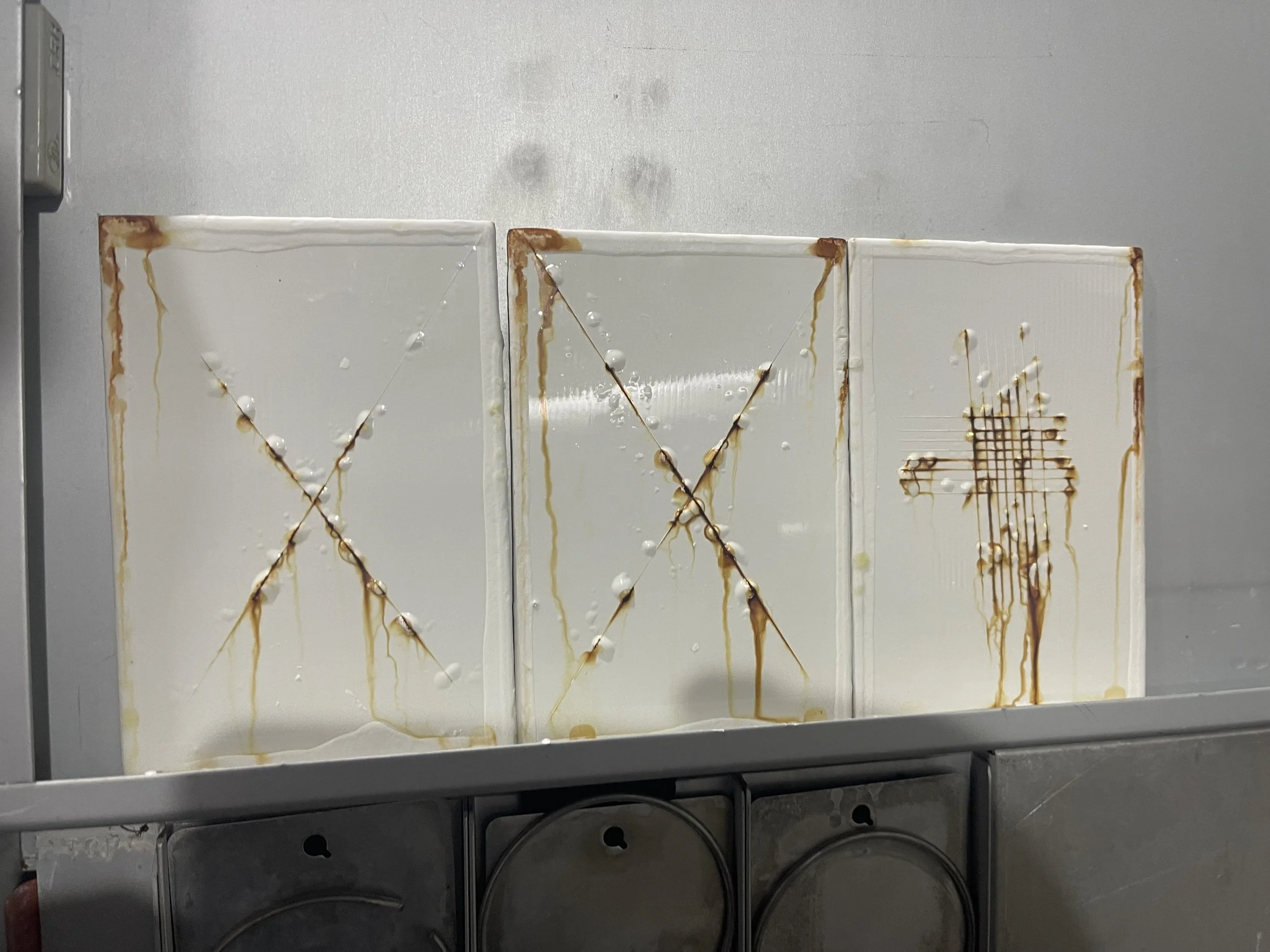

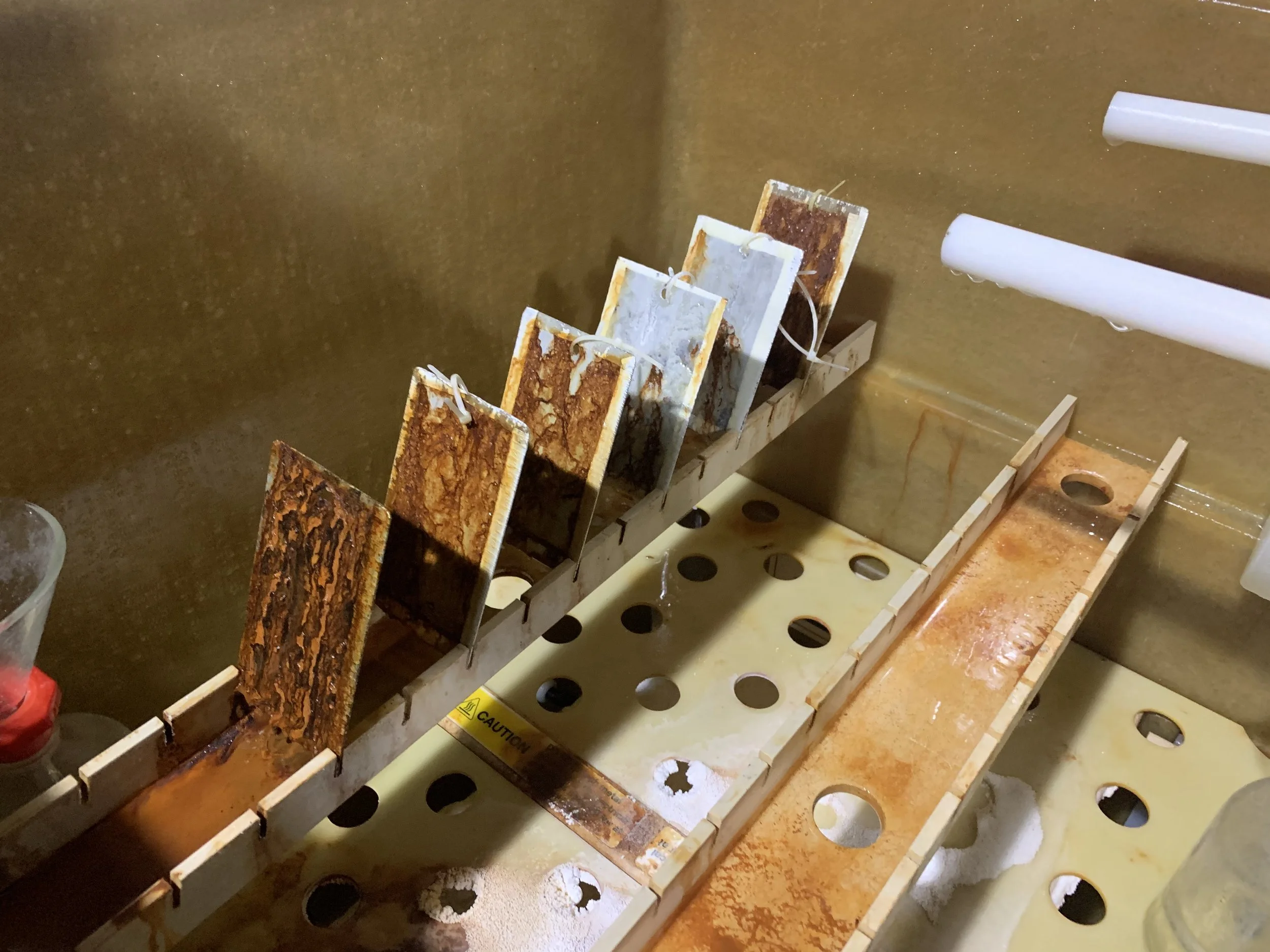

As described this test sprays a solution of 5% sodium chloride mixed with deionised water onto the products. Salt Fog is an alternative description and one that really fits better. The solution is sprayed using a nozzle that injects compressed air, causing a heavy fog of corrosive humidity to fill the chamber. This fog condenses on the samples under test, which is why samples are generally held 15º off of vertical, so that condensate runs off the surface.

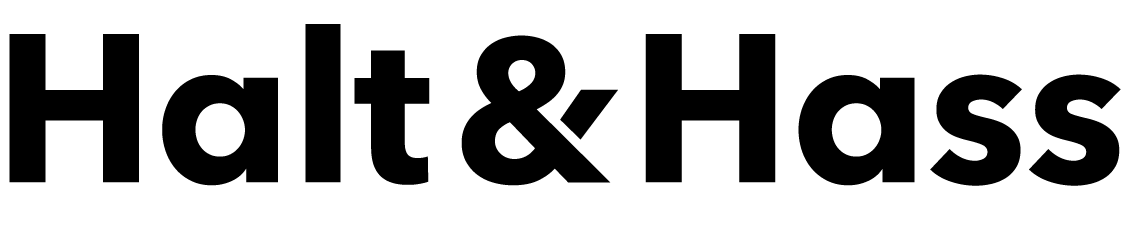

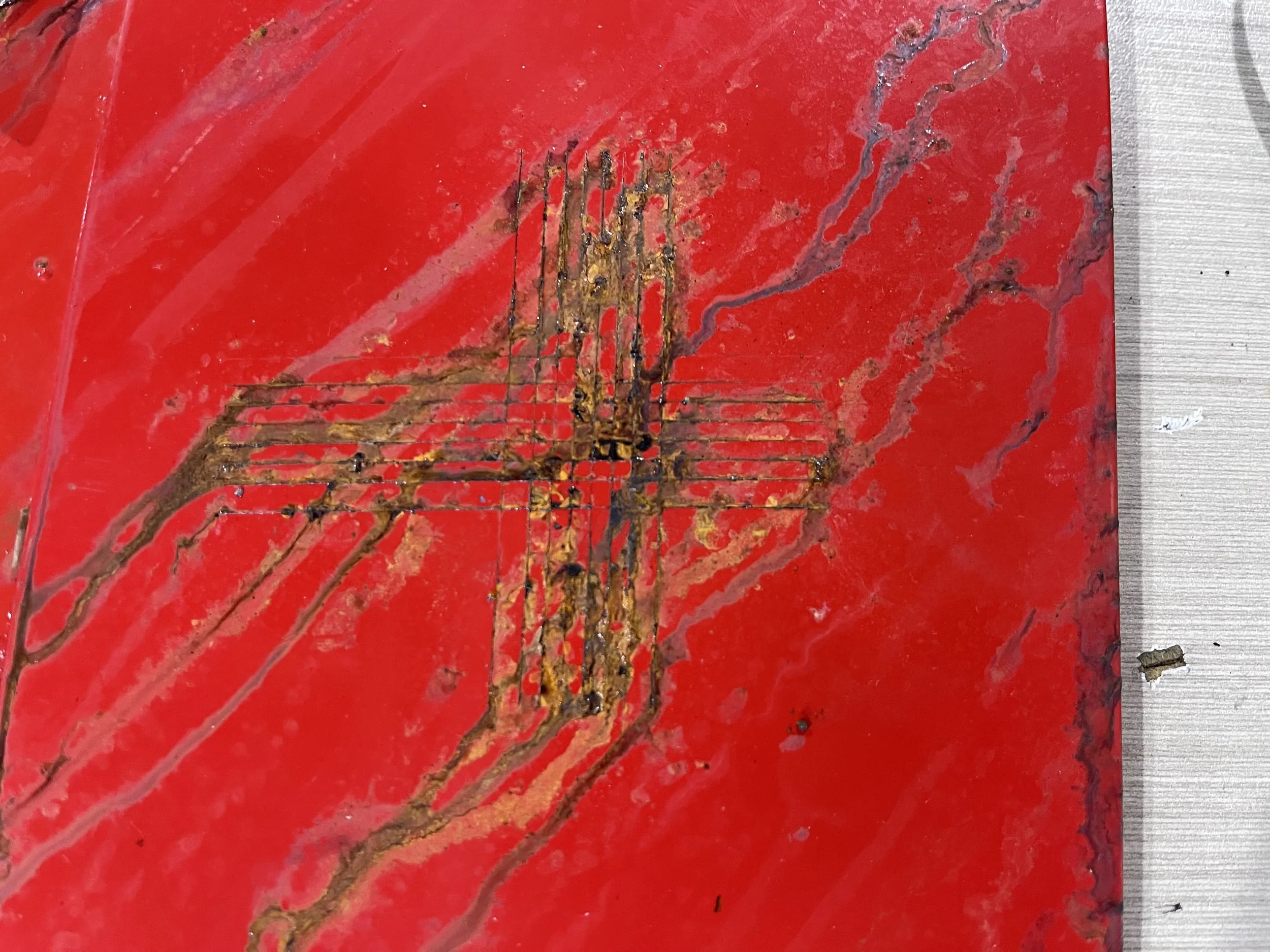

Depending on the product, and the desired outcome, samples can be cross-hatched (paints, coatings, etc.), or tested as-is (trailer parts, metals, etc.), or may even be protected from the fog if they’re in a protected environment (inside, but open to salty air). Conversely, samples exposed to heavily corrosive environments, or very strong materials (SUS316) may benefit from a Copper Acetic Salt Spray (CASS) test which is an accelerated for of the Neutral Salt Spray (NSS) test.

We have two test chambers capable of this method:

Q-Lab SSP600 - Salt Spray (NSS/CASS)

Q-Lab CCT1100 - Salt Spray (NSS/CASS) + Cyclic Corrosion

Various standards exist, however the common ones are:

ASTM-B117

ISO-9227

ISO-12944

Cyclic Corrosion Testing

Similarly, as-described, this test imparts a cyclic process rather than a constant salt spray (fog) to the samples. Typically this includes salt spray, drying, wetting and humidity control but can vary widely depending on the calling standard. Each automotive manufacturer generally has their own preferred method and step profile they insist be executed.

Cyclic corrosion generally applies to galvanic coatings and paints, where the application of wetting cycles encourages delamination of the various layers.

Again, various standards exist, however the common ones are:

GM/Ford

Fiat

BMW/VW/Volvo/Nissan/Toyota

Renault

VDA

Japan JIS Z2371

VDA 621-415

SCAB test

Additional Equipment we Carry

We carry the following equipment to help evaluate product performance, and durability:

BYK Gardner Cross Cut Adhesion Test Kit #5127 – ASTM Standard

BYK Gardner Cross Cut Adhesion Test Kit #5126 – ISO Standard

Range of Scotch tape for adhesion tests

BYK Gardner Micro Tri-Gloss Meter

Calibrated Scales for measuring weight loss

Great Macbeth The Judge II Lightbooth with D65 Lights