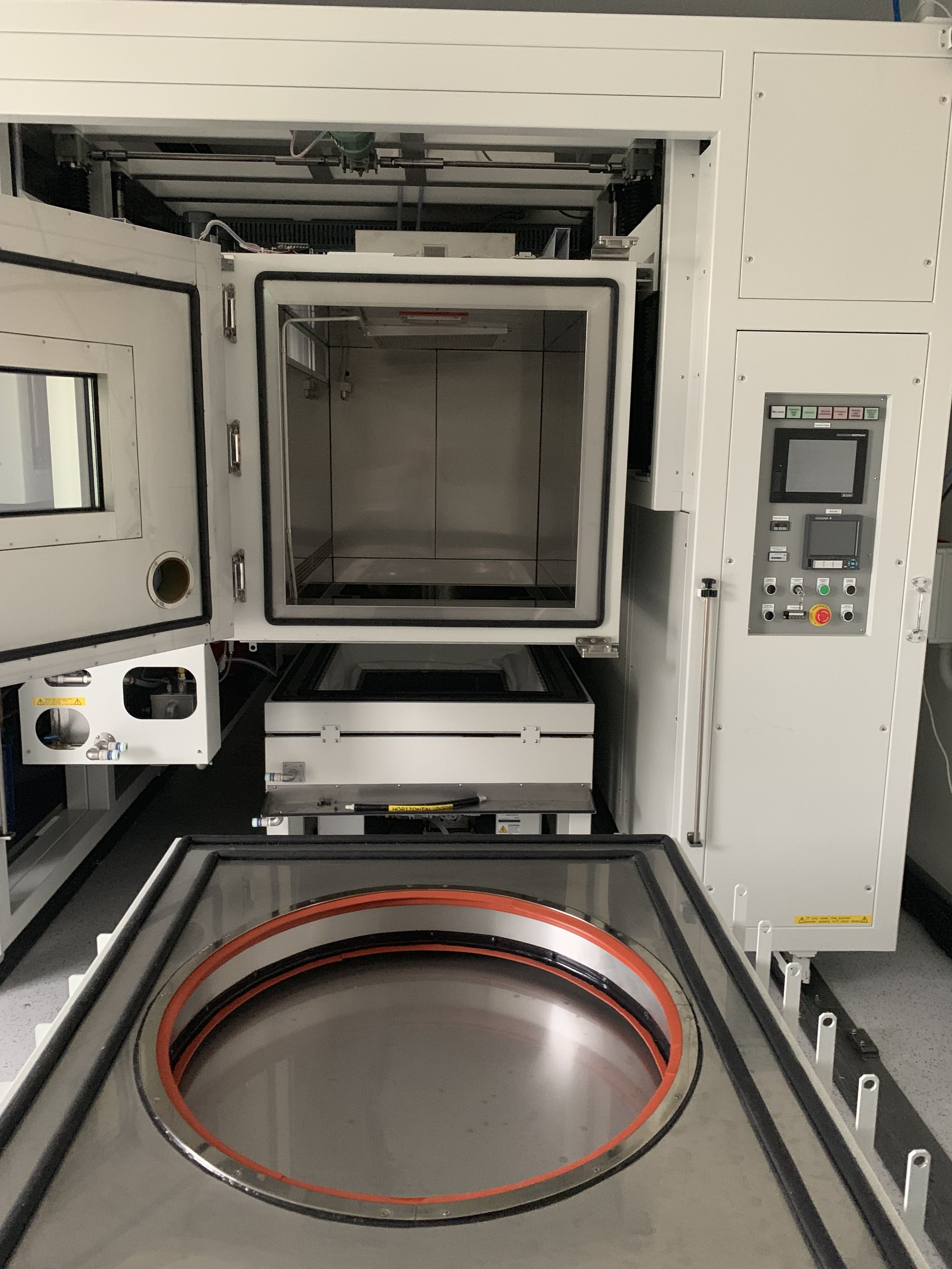

Three Position :: AGREE Combined Chambers

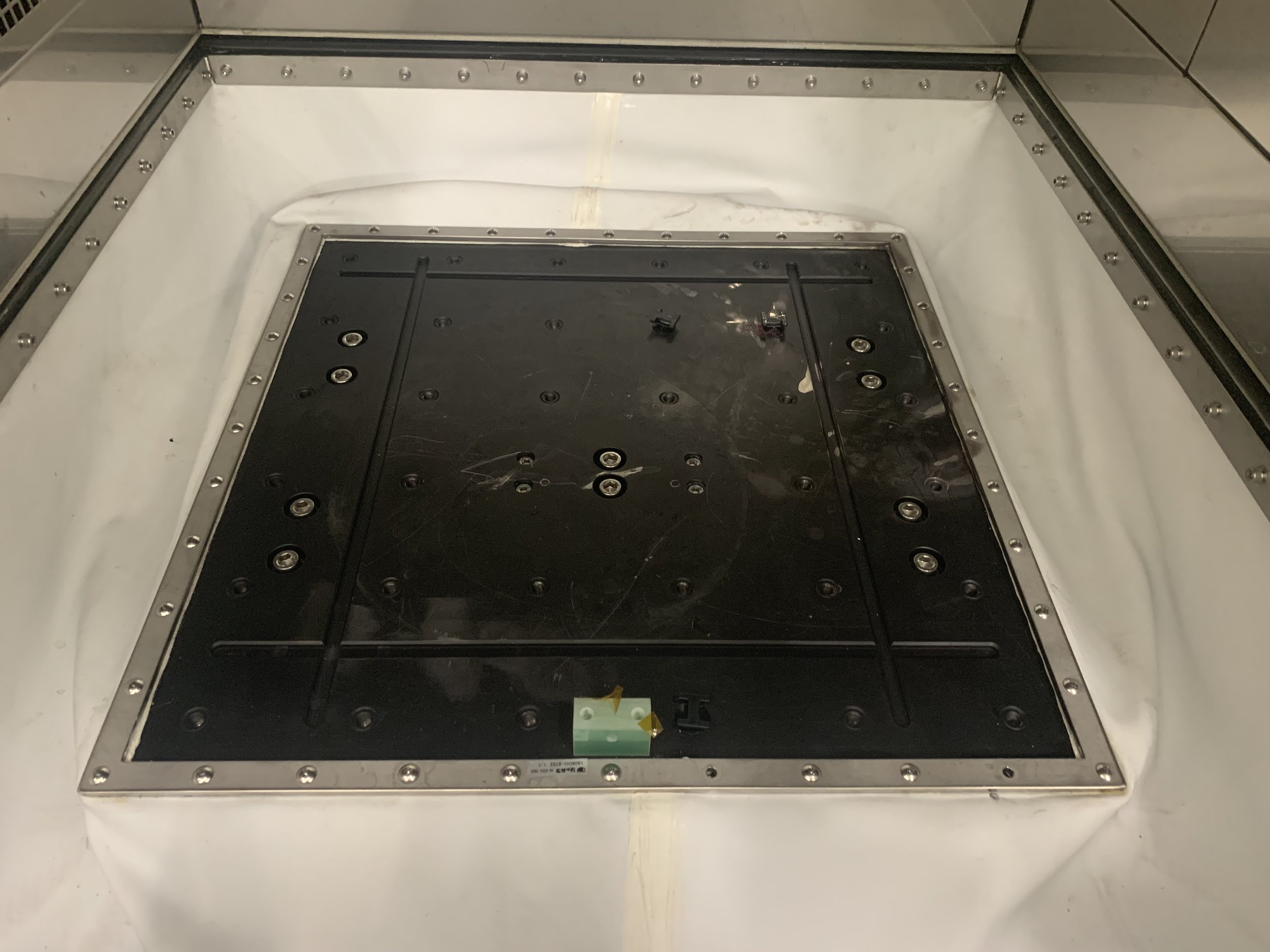

Three-Position Combined Environment chambers support combined testing with the shaker in both the vertical and horizontal orientations, along with a chamber stand-alone mode for when you need to use both systems simultaneously. These chambers can be configured in transverse or longitudinal modes depending on the space available, shaker, and chamber size.

All chambers can be manufactured to suit your current vibration test system - IMV designs and manufactures the interfacing panels required along with safety and homing systems to ensure a reliable coupling to the shaker. the K2+ Controller supports combined control of both systems, allowing for fully integrated reporting and time stamping of events.

IMV can supply vibration-test systems combined with climatic chambers to provide complete vibration, temperature and humidity environmental testing. These systems can be custom-designed to meet your application and specifications.

Combined Environment Test Chamber Specifications

All specifications are able to be customised, chambers are built-to-order to ensure what you receive is exactly what you need.

| Model Number | SYN-3HA-70-VH |

|---|---|

| Internal dimensions | W1000×D1000×H1000mm |

| Temperature range | -70℃ - +180℃ |

| Humidity range | 20% - 98%RH |

| Temperature pull down time |

1℃/minutes or more (Curve gradient) |

| Temperature heat up time |

2℃/minutes or more (Curve gradient) |

| Cooling Type | Air Cooled |

| Voltage | 400V 50Hz 3-Phase |

| Model Number | SYN-2HW-70-VH |

|---|---|

| Internal dimensions | W800×D1000×H900mm |

| Temperature range | -70℃ - +180℃ |

| Humidity range | 20% - 98%RH |

| Temperature pull down time |

+180℃ → -70℃ at 5℃/minute (Curve gradient) |

| Temperature heat up time |

-70℃ → +180℃ at 5℃/minute (Curve gradient) |

| Cooling Type | Water Cooled |

| Voltage | 400V 50Hz 3-Phase |

Installation, Maintenance & Support

HALT & HASS undertakes training for their Engineers at least annually and often more. Training is provided by IMV’s international support division and covers practical, hands-on maintenance application and fault diagnosis.

Shakers are serviced by our experts who understand the adjustments required to keep your system operating efficiently and as trouble-free as possible.

Installation is conducted by our international team and can include everything from de-crating to rigging and moving equipment before final installation and commissioning.